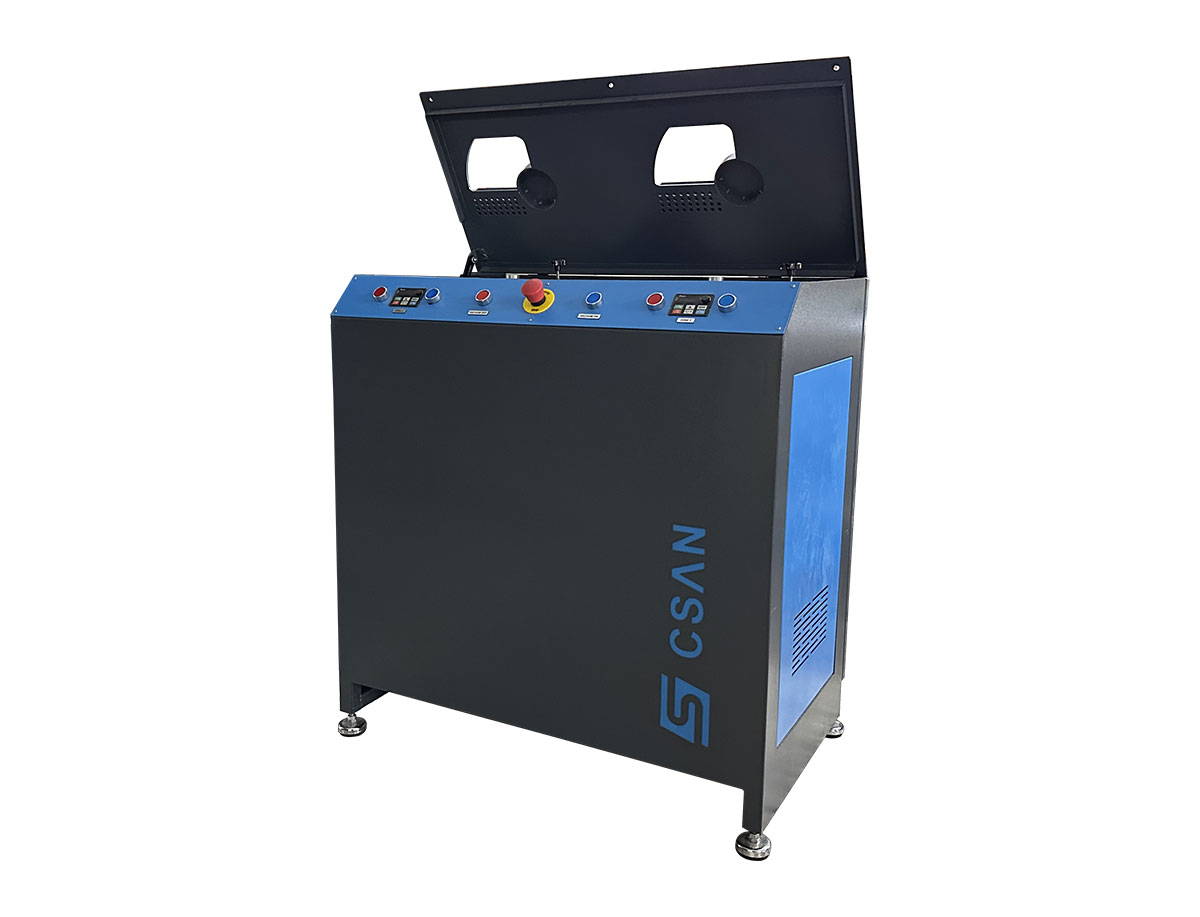

CSAN Polisher

Introduction to the machine

The polisher is one of the key tools in the process of polishing and polishing metal surfaces, and one of the most important aspects of analyzing metal samples (using the quantummetric method), especially steel and brass samples, is preparing the surface of the samples. The polisher, manufactured by the Novin Control System Company, has two discs with a diameter of 35 cm, and sandpaper with different roughness numbers can be installed on it based on the customer’s needs. This feature allows the user to use softer and harder sandpapers depending on the type of work and the desired surface. This device has the ability to adjust the rotation speed of the discs. This feature allows the user to choose the appropriate speed for each type of surface and type of sandpaper. The motor speed usually varies between 1500 and 3000 rpm and is selected depending on the user’s needs. All types of sandpaper can be used in this device, and there is no need to glue or use adhesive or special sandpapers. It is also possible to connect a suction (shavings collector) to the device.

Technical specifications Q’Pol-1

- Disc diameter: 35cm

- Motor speed: 1500rpm

- Input power: 380VAC, 50Hz, 3ph

- Power consumption: 2KVA

- Dimensions: 100cm x 56cm x 54cm

- Weight: 81Kg

Benefits Q’Pol-1

- Low wear

- High durability of the device

- No vibration

- Ability to install sandpaper with different roughness sizes

- Ability to connect to a vacuum cleaner

- Equipped with a timer

Applications of Metallographic Polisher in Different Industries

🔹 Steel Industry:

Metallographic polishing is essential for sample preparation prior to microscopic examination of steel. It enables accurate analysis of microstructure, grain boundaries, phases, and heat treatment effects.

🔹 Copper and Copper Alloys:

For alloys such as bronze and brass, polishing helps reveal dual-phase structures, twin boundaries, and alloy distribution. A mirror-like finish ensures clear observation under optical or electron microscopes.

🔹 Cement Industry:

Polishers are used to prepare clinker, limestone, and raw material samples before SEM or elemental analysis (EDS/WDS). A properly polished surface improves phase identification and analytical accuracy.

🔹 Casting and Foundry:

In the foundry industry, polishing of cast metal samples (iron, aluminum, copper alloys) is crucial for detecting porosity, shrinkage defects, grain morphology, and solidification patterns. It enhances the precision of structural defect evaluation.